Tested for Quality

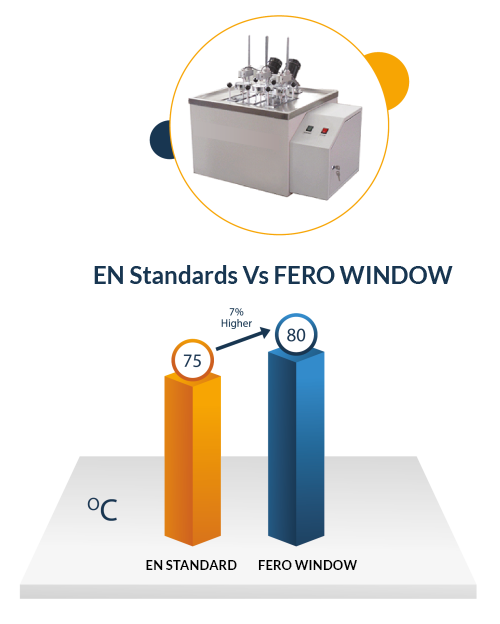

Vicat Softening Temperature (VST)-(EN ISO 306)

Definition

The temperature at which the UPVC test specimen allows maximum penetration of the needle upto 1mm, while it is heated up in an oil bath with simultaneous applications of load(10N-50N) on the needle.

Consequences

Lower VST indicates poor formulation strength and deteriorates in early stages. Windows may deteriorate even at lower temperature.

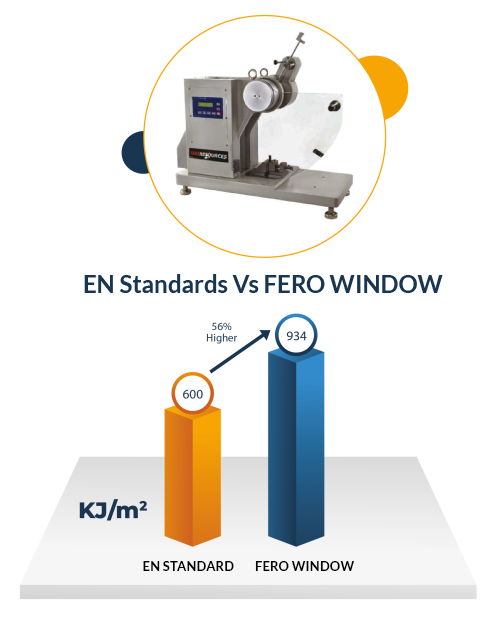

Tensile Impact Test (EN ISO 8256)

Definition

The method of investigating the behaviour of the brittleness and toughness of UPVC specimens under specified impact velocities.

Consequences

Poor mechanical strength is more vulnerable for impact loads on Windows.

EN Standards Vs. Blue Whale

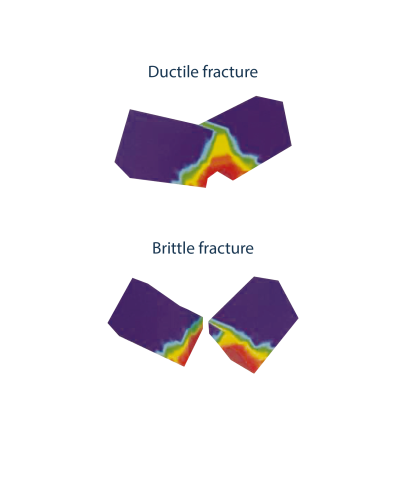

Ductile Fracture

Type of Fracture characterized by extensive deformation of plastic or “necking” resulted by finest grades of raw material used for extruding window Profiles.

Brittle Fracture

Type of Fracture characterized by rapid crack propagation with low energy release and without significant plastic deformation resulted by inferior or coarse grades of raw materials.

Consequences

Poor impact strength results in brittle failure.

Heat Reversion (EN 12608)

Definition

Heat reversion is the behaviour of UPVC Profile to withstand the expansion of contraction at elevated temperature(100°C at 60 minutes in a hot air oven). The value shall not be >2% in thelargest opposing sight surfaces. Heat reversion difference shall not be >0.4% of two visual surfaces.

Consequences

Window warpage issue.

Heat Aging (EN12608)

Definition

Heat reversion is the behaviour of UPVC Profile to withstand the expansion of contraction at elevated temperature(100°C at 60 minutes in a hot air oven). The value shall not be >2% in thelargest opposing sight surfaces. Heat reversion difference shall not be >0.4% of two visual surfaces.

Consequences

Cracks and rupture on the Window Profile surface due to entrapped gases.

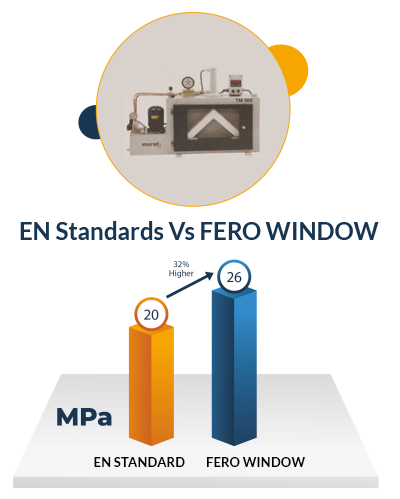

Weld Strength Test (EN 514)

Definition

The measure of molecular bonding strength of fusion welding i.e. The minimum failure load of welded corners.

Consequences

Low weld strength leads to weld cracks and panel cracks during transit and installation of Windows.

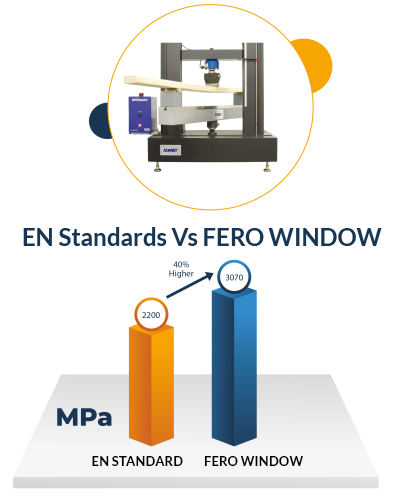

Flexural Modulus of Elasticity Test (EN ISO 178)

Definition

Flexural modulus is the tendency of UPVC specimen to bend i.e. Quantification of stress to strain ratio in Flexural deformation.

Consequences

Poor Elasticity results in more brittleness and vulnerability.

Accelerated Weathering Test (DIN EN 513)

Definition

Accelerated weathering is a simulation of adverse environment conditions to speed up the weathering process to evaluate the compatibility of UPVC Profile against extreme tropical weather conditions.

Measure of ΔE value of UPVC Profile specimen through simulation of severe climatic zone ‘s’ at 10000 hours @20Gj/m² of radiation.

Consequences

ΔE Value beyond 5 leads to discolouration hazard and cannot comply with any warranty commitment, whereas Blue Whale complies with ΔE belows 2.

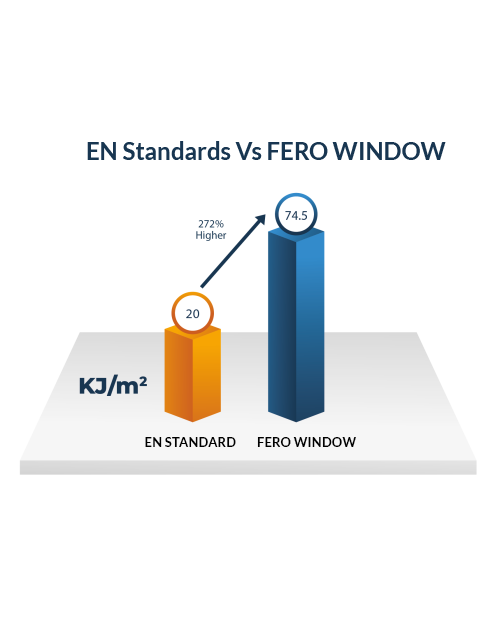

Charpy Impact Strength Test (EN ISO 179)

Definition

Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by UPVC during fracture.